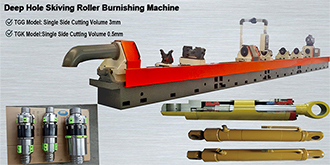

- Deep Hole Skiving, Roller Burnishing Machine

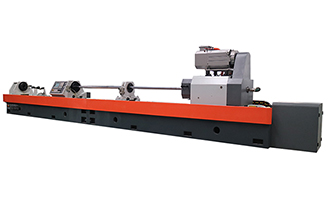

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

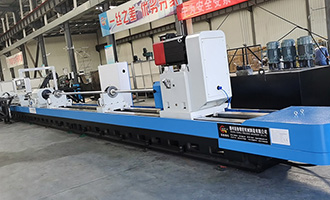

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

TG2115 is the machine that speciallized for small diameter hot steel pipe. The machine design refers to Sierra of USA,combined rough boring, precision skiving & burnishing into one process. High efficient and high precision.

Item name |

Parameters |

|

Boring bar box spindle parameters |

Boring hole diameter range |

Ф36-Ф150mm |

Job length |

2000mm |

|

Center height |

> 200mm |

|

Boring bar box spindle front taper hole |

Morse 5 |

|

Spinle speed range |

100-1500r/min (AC servo motor. infinitely variable speeds) |

|

Spindle output torque |

≥280N.m |

|

Infeed parameters |

Infeed speed range |

5-2000mm/min (infinitely variable speeds) |

Carrier rapid movement |

3m/min |

|

Motor power |

Boring bar motor power |

45KW AC Servo motor |

Infeed motor |

28NM AC Permanent magnet servo motor |

|

Job clamping hydraulic pump motor |

1.5KW AC motor |

|

Output coolant pump motor power |

15KW, 1set paddle pump |

|

Auto lubricate motor power |

0.2KW, 1set |

|

Gerneral power |

68KW |

|

Control |

Siemens CNC |

|

Others |

Coolanty system flow |

200L/min |

Coolant system rated pressure |

3Mpa |

|

Filtering accuracy |

40um |

|

Coolant chamber volume |

4CCBM |

|

Max clamping force to the job |

3KN |

|

Machine dimension |

(8000mm)X2500mmX1550mm |

|

Weight |

about (13)T |