- Deep Hole Skiving, Roller Burnishing Machine

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

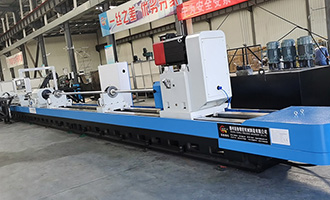

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

The deep hole pulling boring machine can work on inner hole pull-boring, expand and rolling-pressing. When pull boring machine work, workpiece will static(not rotary), cutter rotary and infeeding, the cutting liquid will enter to cutting area through oil provide device, cooling and lubricating the cutting area and bring the chips away. When deep hole pull boring works, it adopts auto chips removal method, the chips will be discharged thorugh the front chips box.

Rough boring: hole diameter accuracy IT9-10. Surface roughness: Ra6.3.

Precision boring: hole diameter accuracy IT8-9. Surface roughness: Ra3.2.

Rolling-pressing: hole diameter accuracy IT8-9. Surface roughness: Ra0.2.

Holes straightness: Less than 0.15/1000mm.

Holes exit screwness: Less than 1/1000mm.

Deep hole pull boring machine processing efficient

Cutting speed: according to cutters' struction, cutters'material and workpiece material, normally speed is 50-150m/min.

Infeed speed: according the requirement, normally 5-500mm/min.

When boring, the Max.processing finish allowance: according the cutter's struction, cutters'material and workpiece condition, single side processing amount less than 10mm.

Specifications |

Technical data |

Boring diameter range |

Φ40-Φ350mm |

Boring max.depth |

6.5m |

Center height (from level guide to spindle center) |

450mm |

Drilling bar box spindle bore diameter |

Φ30mm |

Spindle front taper hole |

Flange, press and tight connection |

Spindle speed range, grade |

0~1050r/min 2gear stepless |

Main motor |

75kw variable frequency motor system (or 60kw: hypersynchrony) |

Infeed speed range |

5~300mm/min (A.C servo motor stepless ) |

Carrier rapid speed |

2m/min |

Workpiece clamp diameter range |

100~400mm |

Infeed motor |

7.5kw (A.C servo motor, stepless) |

Carrier rapid motor |

3kw |