- Deep Hole Skiving, Roller Burnishing Machine

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

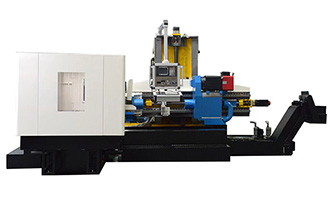

Three Coordinate Deep Hole Gun Drilling Machine

ZKB2102 deep hole drilling machine is also a three coordinate deep hole gun drilling machine, this three coordinate deep hole gun drilling machine is suitable for working with special sharped workpiece, the deep hole diameter range and deep hole depth can be manufactured according to customer's requirement.

ZKB2102 Three coordinate deep hole gun drilling machine is mainly used for glass moulds, hydraulic tools, rubber moulds of water holes, oil holes, heat holes and so on.

Gun drilling techincial (exteral chip remove system)

Can work on Coordinate deep holes workpiece

Deep hole diameter: φ4mm~φ20mm

Max depth: 500mm

CNC system: FANUC 0i MATE or GSK

ZKB2102 deep hole drilling machine (gun drilling machine) is used for drilling three or two coordinate holes deep-hole machining equipment with properties of high efficiency, high accuracy and high automation. So it is also called three coordinate deep hole gun drilling machine.

ZKB2102 deep hole drilling machine (gun drilling machine) adopts external-chip removing method (gun drill method) through one continues drilling, it can instead of traditional drilling, expanding and reaming procedure and arrive the machine accuracy and surface roughness requirement in one time. The deep hole accuracy is IT7-IT10, roughness is Ra3.2-Ra0.04 um, the center straight line is less than 0.05mm every 1000mm.

ZKB2102 Three coordinate deep hole gun drilling machine is controlled by CNC system with function of both single action and automatic recycling. So that it can not only meet the requirements of small batch, but also can meet large batch.

ZKB2102 deep hole drilling machine can drill through hole, blind hole and step hole. It can be widely used in the industry of automobile and motorcycle, mould, military and aeronautics.

1. Fix the workpiece on the working table.

2. Pneumatic system control guide suite of the guide frame.

3. Start the cooling system high pressure pump group.

4. Start the drilling bar box, drive the driller rotary.

5. Z axis infeed system drive driller infeed.

6. After drilling to the setted position, driller return, coolant stop, sealed guide suite loose.

7. X, Y axis move to the next drilling position, repeat 2 to 7.

2~7 steps are completed by CNC control

Specification |

Parameters |

Remak |

|||

Working capacity |

Drilling diameter range |

Φ4~Φ20mm |

|||

Drilling max depth |

500mm |

||||

Machine character |

Z axis |

Infeed speed range |

5~500mm/min |

Stepless |

|

Rapid speed range |

3000mm/min |

||||

X axis |

Traval |

650mm |

(make according to customer request) |

||

Y axis |

Travel distance |

500mm |

|||

Drilling bar box |

Speed range |

500~6000r/min |

Stepless |

||

Motor power |

4KW |

Inverter motor |

|||

Machine loading weight |

500kg |

||||

Hole length-diameter ratio |

≤100 |

||||

CNC system |

FANUC or GSK |

||||

Coolant systyem |

Coolant system pressure range |

0~8MPa |

Adjustable |

||

Coolant system flow range |

0~63L/min |

Adjustable |

|||

Filter accuracy |

20μm |

||||

Oil chamber volume |

800L |

|

|||

Machine body

Drilling bar box

Infeeding system (Z axis)

Coolant system

Oil temperature controller machine

Auto chips removal device (note: iron material/steel material use magnet chips removal device, while copper material use scraping belt, please indicate which you like, if you wants both, price increase USD1200)

Elevator (Y axis) and T working table (X axis)

Central lubrication system

Pneumatic control system

Guide frame system

Drilling bar support system

FANUC or GSK CNC control system

Oil chamber filter device and filter paper

Overflow valve