- Deep Hole Skiving, Roller Burnishing Machine

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

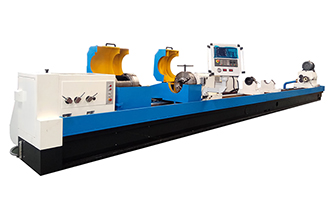

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

1) Drill hole method: Gun drilling method. The machine is used for processing concentric hole on cylindrical workpieces. Both workpiece and cutter can rotate.

2) When boring, adopts front chips removal method. It means the chips will flow out from headstock front end.

3) Workpieces load and unload adopts two-ends cone disc automatic tighten method, both ends of workpiece are chamfered.

4) The user should provide the chamfer size of workpiece both ends and workpiece size when ordering the machine.

5) The machine adopts linear guide rail.

6) The machine equips with full safety guard with six doors and oil mist collector.

7) Cutter spindle is driven by servo main motor and Synchronous belt, stepless speed adjustment can be realized. Main motor power is 7kw, spindle rotary speed range is 500~6000r/min.

8) Cutter infeed movement adopts structure of servo motor, spring coupling and ball screw, speed stepless.

9) The machine equips with 10 pieces of dill bar support rest, the distance between drill bar support rest will keep the same under any conditions. Length of 10 pieces drill bar support rest getting together is 360mm. Length of guide frame is 160mm.

10) Guide frame of drill head can do axial movement for 50mm driven by hydraulic cylinder.

11) Guide rail used for workpiece tighten, loosen and movement is linear guide rail.

12) Adopts four sets center frame to support the workpiece. Suitable for workpieces with outer diameter range Φ10~Φ40mm; Center frame upper cover adopts cylinder automatic open and close.

13) Headstock drives the workpiece to turn, adopts servo main motor and synchronous belt to drive the spindle to rotate, speed stepless can be realized. Spindle front end adopts cone disc and chuck head body structure.

14) Machine coolant system include chain plate chips conveyor, magnetic roller filter, paper filter, oil temperature controller, high pressure frequency conversion pump groups and liquid level controller. The cutting oil pressure and flow can be adjusted according to hole diameters, and the value of flow and pressure can be shown also.

Specification |

Parameter |

Remark |

||

Working Capacity |

Drill hole diameter range |

Φ3~Φ20mm |

- |

|

Max. depth of drill hole |

2500mm |

- |

||

Max. Workpiece length |

2500mm |

- |

||

Workpiece OD range |

Φ10~Φ40mm |

- |

||

Machine Character |

Z axis |

Infeed speed range |

5~500mm/min |

Stepless |

Rapid move speed |

3000mm/min |

- |

||

Infeed motor torque |

11Nm |

- |

||

Drill bar box |

Rotary speed range |

500~6000r/min |

Stepless |

|

Motor power |

7KW |

Servo spindle motor |

||

Headstock |

Rotary speed range |

50~100r/min |

Stepless |

|

Motor power |

7KW |

Servo spindle motor |

||

Coolant system |

Coolant system pressure range |

1~10MPa |

Adjustable |

|

Coolant system flow range |

6~100L/min |

Adjustable |

||

Filter accuracy |

20μm |

- |

||

Oil tank volume |

>1000L |

- |

||