- Deep Hole Skiving, Roller Burnishing Machine

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

One Side Can Be 5mm Processing Margin

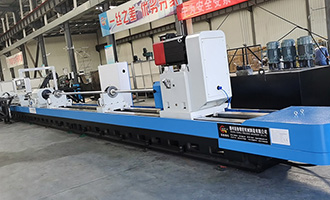

TGG2115x4000mm deep hole scraping boring machine has a big ration power, a high rigidity, a wide allowance of machining process, and a very high machining efficiency, as ideal equipment suitable for machining various cylindrical deep-hole work pieces, capable of machining various mechanic hydraulic oil cylinders, the through-holes and stepped holes, of cylindrical work pieces, etc. The machine is mainly used for bore and roll machining. The machine adopts the fine-scraping and rolling integrated machining process based on the rotation of boring tool. Front-row scraping is adopted for boring. The boring way is push boring, oil feeding by oil feeder at the center of boring bar and headstock chip removal. Rolling is post-tensioning rolling. Korean SRB high-speed scraping/boring rolling head is applied. The application of this machine will bring an epoch-making revolution to the production process of oil cylinder. The cylindricity and the concentricity of machining work piece are very high. The cutting and rolling speed of producing oil cylinder with cold drawn pipe can reach 1.2 meters/min.

The machine body is manufactured with high-quality cast iron, with a high rigidity. The resin cement is used to irrigate the inside of machine body, with a very strong stability. The main shaft adopts a Beijing CTB 50KW ac servo drive, and the main shaft of boring bar box combines a 3-gear manual and servo drive for speed adjustment, with a wide scope of speed adjustment and a large torque. The feeding system adopts a Beijing CTB 9KW ac servo motor drive, and Φ80 ball screw transmission, with a steady feeding and a long service life, capable of meeting various deep-hole machining process requirements. The work-piece mounting adopts a hydraulic oil cylinder for tight propping, and combines tight clamping with hydraulic calipers, steady, reliable and convenient for loading/unloading. The electrical system adopts German Siemens 808 D CNC system for centralized control, capable of human-machine interaction and picture display, flexible to operate, safe and reliable.

In production it is suitable for mass production can also be suitable for small batch production. TGG2115x4000mm deep hole scraping boring machine is the best choice for producing hydraulic oil cylinder equipment.

|

Item |

Parameter |

Working scope |

Boring hole diameter range |

Ф38-Ф150mm |

Workpiece length |

4000mm |

|

Boring bar box spindle parameters |

Center height |

> 300mm |

Leading end of cone hole boring bar box spindle |

Ф80mm 1: 20 |

|

The spindle speed range |

50-1800r/min (Ac frequency conversion stepless speed regulation) |

|

Output shaft torque |

≥1000N.m |

|

Feed parameters |

Feed speed range |

5-2000mm/min (stepless) |

Plate moving fast |

3m/min |

|

Machining accuracy |

Locate the length |

0-4m |

Workpiece surface roughness of boring |

≤Ra3.2μm |

|

Workpiece surface roughness of rolling |

≤Ra0.8μm |

|

Workpiece machining straightness |

≤0.05/500 mm |

|

Workpiece machining roundness |

≤0.029/200mm |

|

Motor capacity |

Boring bar motor power |

30KW Ac servo motor |

Feed motor |

5.5kw Ac servo motor |

|

Hydraulic pump station motor |

1.5KW Ac motor |

|

Output cooling pump motor power |

7.5KW one set |

|

Automatic chip removal motor power |

1.5KW one set |

|

Magnetic separator motor power |

0.75KW one set |

|

Centralized lubrication motor |

0.75KW one set |

|

Others |

Head of the biggest pre-tightening force for the workpiece |

30KN |

The cooling system flow |

200L/min |

|

Cooling system rated pressure |

0.36Mpa |

|

Magnetic separator flow |

300L/min |