- Deep Hole Skiving, Roller Burnishing Machine

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

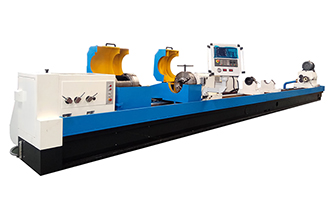

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

TK2125 CNC deep hole drilling and boring machine are specially for the cylindrical workpiece, such as lathe's spindle holes, through holes, blind holes, step holes of all kinds of machinery hydralic oil cylinders, air cylinders, the machine can drill, bore and also press, it is adopted BTA chip-out method.

The body of TK2125 CNC deep hole drilling and boring machine is good in regidity, high accuracy. The spindle speed range is wide, infeed system is driven by AC servo motor, which can meet all kinds of deep hole process, the oil supply fasten device and workpiece clampling device adopts hydralic system, and show the pressure value, safety and reliable.

We can also make similar machines basing on the above machine, different length. We can make this kind of deep hole drillingand boring machines according to customers' requirement.

The machine is special equipment for machining deep cylindrical hole of work pieces. It can be perfectly suited for boring, through holes, blind and step holes in workpieces; Such as, apindle of various kinds of machines, many kinds of hydraulic oil cylinders and cylinders and drill collars in the gas and oil field.

It adopts BTA processing method, it can not only drill the deep holes, but also bore the deep holes. When drilling the workpiece, it adopts BTA chip remove method, that is: the coolant liquid arrive the drilling parts through oil supply device, the iron chips and coolant oil return to the drain back tank and chips removal device through the drilling bar hole. Through the above method to realize the drilling purpose.

When boring the workpiece, we adopts pull boring front chip removal method(pull the boring head go ahead, and remove the front chips by that way), the headstock spindle front equips chips removal device, used for boring and chips remove. When boring the workpiece, the workpiece rotary, so as to enhance the boring accuracy. The workpiece adopts double taper plate fasten position, workpiece fasten easily. Position liable.

Items |

TK2125 |

Drilling diameter range |

30mm to 120mm |

Max.diameter for boring |

250mm |

Boring diameter range |

40-250mm |

Max. depth for drilling and boring |

Max lenth can be 12meters. |

Chuck diameter for clamping work piece |

60mm -300mm |

Height from spindle center to machine bed |

350mm |

Speed range for spindle |

61-1000r/min (11kinds) |

Infeed speed range (stepless) |

5-1000mm/min |

Rapid travel speed for carriage |

2m/min |

Main motor power |

30kW |

Hydraulic pressure pump motor power |

1.5kW |

Carriage fast moving motor power |

3kW |

Infeeding motor power |

3.7kW |

Cooling pump motor power |

4kw |

Rated pressure for cooling system |

2.5MPa |

Flowing for cooling system |

200 L/min |

Rated working pressure for hydraulic system |

6.3MPa |

Control system |

Simenz or KND |