- Deep Hole Skiving, Roller Burnishing Machine

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

Gun drilling machine also known as deep hole drilling machine, got its name from original usage used Military Industry, hence the name gun drilling, deep hole machining, which has won itself a convenient and efficient way of processing, as technology keeps developing and with unremitting efforts by system manufacturers, covers various applications such as: automobile, aerospace, structural construction, medical equipment, molds, tools, jigs, hydraulic, air compressor industry as well as other fields.

By providing precise machining, accurately machined position for hole, high linearity and co-axiality, excellent surface finish and slight tolerance, gun drill becomes ideal solution for deep hole machining. Gun drilling machine fits for various hole machining. With considerable technical reliability, gun drill can totally replace drill-and-ream Process with its unique one-time-processing.

The drill of gun drilling machine is mainly used for drilling holes of small diameter, about 1.5mm-38mm, drilling length-to-diameter ratio is 150(diameter x 150). (That means maximum drilling depth), high pressure coolant gets to cutting site through the spindle and the drill bit. Iron chip will be discharged through the V-groove on the drill bit.

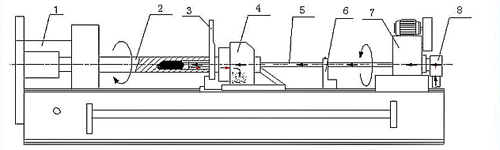

1. Spindle Box |

2. Workpiece |

3. Central Bracket |

4. Chip-discharger |

5. Drilling Gun |

6. Drilling Bar Bracket |

7. Drilling Box |

8. Oil-supply |

Prior to use, suitable guide sleeve should be chosen and a 0.003mm--0.008mm distance should be kept between guide sleeve and the drill bit. Spindle used for drilling gun should be of higher axial and radial stiffness, and higher co-axility between guide sleeve and spindle is required. No any crack, gas-hole or other matters are allowed to be appear in the location of the drilled (specially for casting), which might cause tipping and drill-bit dropping. Cutting amount should be chosen properly. Normally, cutting speed: V=1.1-1.65 m/s, Feed Rate: s=0.015-0.03mm/rev, oil pressure: P=2.5-6.0Mpa, flowrate: Q=0.2-0.65L/s.

Cutting liquid for drilling could significantly and immediately affect the accuracy of holing, so drilling-specific oil should be used. In most cases, cutting oil for drilling gun would equipped with extreme additives to create an oil membrance to avoid draught grinding. Viscosity of cutting oil depends on drilling diameter. The shorter diameter is, the lower viscosity is obtained. On contrast to typical machine, the cutting oil sent to cutting area seems to be of higher pressure, larger flow and higher accuracy of filtration. Flow rises as hole-depth increases to assure faster flow for chip-discharging.

Correct grinding on time as soon as drill bit get worn. Grinding should be conducted on universal or special cutlery grinder, with drill gun mourned on a dedicated clamp and with resin bonded diamond wheel of particulate size 120 to repair only rear edge surface of inner and outer angels each time. Proper geometric angel (drawing provided by us) and tip position should be assured.

Our gun drilling machine holing can handle drilling diameter of Φ1.2mm-Φ40mm, a maximum 2.5m length and upto 4 spindles, which is widely used in Military Barrel, Rear Fin; Water-hole, Pin-hole, Electrothermal hole in plastic molding; valves, distributor, pump and fluid cylinder in hydraulic machinery; engine cylinder, oil-supply & transmission system parts, steering mechanism chassis and steering shaft for Auto Industry, as well as small holing for textile machinery, instruments, apparatus, diesel generator and printer.

Difference between BTA drilling and Gun drilling comes to the way cooling fluid enters and chip discharges. For BTA, cutting oil is driven into cutting site by Coolant Supply and then carries iron chips into drill bit and drill bar's inner hole for chip-discharge. In the case of large hole (bigger than 40mm), the BTA drilling is preferred.

Adopting internal chip-discharging strategy, which handles diameter from Φ20mm to Φ80mm (Boring), our T2120 Series Deep Hole Boring Machine's drilling, boring and rolling functions are applicable to propeller, landing gear and ejection seat; various barrels in military use; heat exchanger pad in power plant; roller in metallic, all rotating parts for gas cylinder, fluid cylinder and spindle; pipes in casting and forging with accuracy of T17, roughness(drilling) of Ra12.5 and roughness(boring) of Ra6.3 as well as roughness(after rolling) of more than Ra 0.4. These Products' Boring Diameter ranges fromФ40mm to Ф200mm, with maximum length -10m. Our maximum Boring Machine can handle Boring Diameter – 1000mm(T21100).

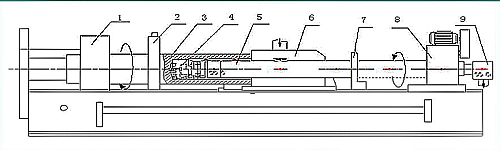

1. Spindle Box |

2. Central Bracket |

3. Workpiece |

4. Drill Head |

5. Drilling Bar |

6. Oil-supply |

7. Drilling Bar Bracket |

8. Drilling Box |

9. External Chip-discharger |

|