- Deep Hole Skiving, Roller Burnishing Machine

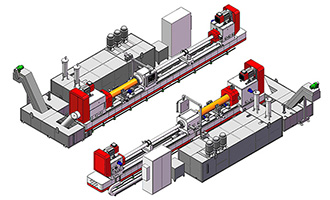

- TGG2116(2M) Deep Hole Skiving Burnishing Machine

- TG2115(1.5M) Deep Hole Skiving Roller Burnishing Machine

- TG2115(6M) Deep Hole Skiving Roll Burnishing Machine

- TG2Zx2106mm Double Spindle Deep Hole Skiving Roller and Burnishing Machine

- TG2115 Deep Hole Skraping Boring Machine

- TGG2115 Deep Hole Skrape Boring Machine

- TG2125 Deep Hole Skraping Rolling Machine

- TG2115(8M) Deep Hole Skraping Burnishing Machine

- Deep Hole Drilling and Boring Machine

- NTK 2120 BTA Deep Hole Drilling and Boring Machine

- BTA Deep Hole Drilling Machie Drive By Rack And Pinion

- BTA Deep Hole Drilling Machine for Aerospace Components

- BTA Deep Hole Drilling Machine for Drill Collar

- Deep Hole Trepaning Machine

- BTA Deep Hole Drilling Machine for Hydraulic Cylinders

- BTA Drilling and Gundrilling Combined Machine

- CNC BTA Deep Hole Drilling Machine for Twin Barrels

- T2120 Deep Hole Drilling and Boring Machine

- T2125 Deep Hole Drilling and Boring Machine

- T2135 Deep Hole Drilling and Boring Machine

- T2150 Deep Hole Boring Machine

- T2180 Deep Hole Trepanning Machine

- T2120G Deep Hole Drilling and Boring Machine

- T2250A Deep Hole Drilling and Boring Machine

- TK2120 CNC Deep Hole Drilling Machine

- TK2125 CNC Deep Hole Drilling Machine

- TK2136 CNC Deep Hole Boring Machinee

- TSK2108 CNC Deep Hole Drilling Machine

- TH2120 Deep Hole Boring and Honing Machine

- Deep Hole Pull Boring Machine

- Gun Drilling Machine

- NZK2103(1500mm) Gundrilling Machine

- NZK2102(2500mm) Gundrilling Machine

- ZSK2103A(1M) Three Axis Gundrilling Machine for Molds or Blocks

- Four Spindles Gundrilling Machine for Orthopaedic Implant

- Double Spindle Gundrilling Machine for Thermal Well

- Three Axis Deep Hole Drilling Machine for Bottle Molds

- Three Axis Deep Hole Drilling Machine for Valve Parts

- ZKB2102 Three Coordinate Deep Hole Gun Drilling Machine

- ZKB2103 Three Axis Gun Drilling Machine

- ZKB2103A Economical Type Deep Hole Gun Drilling Machine

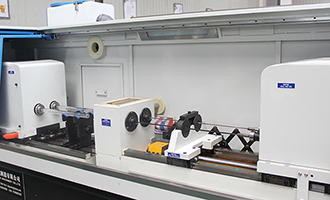

- ZSK2101×500mm Deep Hole Gun Drilling Machine for Medical Device (Small Holes)

- ZSK2103A×300mm Gun Drilling Machine

- ZSK2103×2×500mm Gun Drilling Machine

- ZSK2103×2×1000mm Double Spindle Gun Drill

- ZSK2103×4×500mm Four Spindle Gun Drilling

- ZSK2104×1000mm Gun Drilling Machine

- ZSK2104×1500mm Gun Drilling Machine

- ZSK2104×2000mm Gun Drilling Machine

- ZSK2104×2500mm Deep Hole Machine

- ZMK2102 Gun Drilling Machine(Drill Glass)

- Deep Hole Drilling Machine For Quartz Glass Rods

- Deep Hole Honing Machine

- 2M2150(10M) Deep Hole Honing Machine

- Deep Hole Honing Machine with Ten Meters for Hydraulic Cylinder Repairing

- CNC Deep Hole Honing Machine

- PLC Deep Hole Honing Machine

- 2M2125L Deep Hole Honing Machine

- 2M2125A Deep Hole Strong Honing Machine

- 2M2125 Series Deep Hole Honing Machine

- Deep Hole Heads and Toolings

- Deep Hole SRB Machine Heads

- BTA Drill Heads,Bore Heads,Honing Heads,Bar

- Accessories for Gun Drilling Machines

- LGX300 CNC Spiral Groove Milling Machine

- Quartz Glass Drilling and Honing Machine

Failures |

Possible causes |

Unsmooth chip-discharging |

1. leakage of cutting liquid 2. improper geometric dimension of cutlery 3. cutting liquid over-viscose 4. wrong parameter set for feeding |

Poor chips generated |

1. improper geometric dimension of cutter 2. low linear speed for cutting 3. uneven distributing of material on workpiece |

Damaged drill bit |

1. abnormal feeding 2. clogged chip-discharging 3. poor co-axiality between spindle and guiding support 4. inappropriate cutting liquid 5. higher or lower feed rate 6. excessive axial endplay on the spindle 7. poor materials of cutters |

Short life for cutters |

1. over-temperature of cutting liquid 2. poor co-axiality between spindle and guiding support 3. improper geometric dimension of cutter 4. inappropriate cutting liquid 5. higher linear speed for cutting or higher feed rate 6. inferior cutting liquid 7. lower precision filtration for cutting liquid 8. unstable feeding |

Excessive deflection of workpiece central line |

1. poor co-axiality between spindle and guiding support 2. inappropriate size of guide sleeve of drill bit 3. curved drill bar caused by high feed rate 4. uneven distributing of material on workpiece 5. inappropriate geometric angle of cutters |

Poor surface finish |

1. low linear cutting spead 2. inappropriate geometric dimensions of guide pad 3. improper pressure of cutting liquid 4. wrong cutting liquid 5. higher or abnormal feed rate 6. lower precision f iItration for cutting liquid 7. large hole for guide sleeve of drill bit or drill bar 8. vibrating 9. uneven distributing of material on workpiece |

Hole is not round-shape |

1. poor co-axial ity between spindle and guiding support 2. inappropriate geometric angle of cutters 3. incorrect rotary precision of spindle |

1. For typical Drilling of internal chip-discharging, sulfurized oil would be adopted for most materials.

2. For low carbon material, choose pure engine oil.

3. For alloy steel with Cr, Ni, W, cutting oil consisting of chlorinated paraffin with sulfur would be used.And emulsion for casting iron.

4. In order to eliminate chip build-up, normally cutting liquid should contain S and Pi, oil temperature should be kept between 35-40oC and Oil tank volume should not be less than 10 times of the flow produced in a minute.

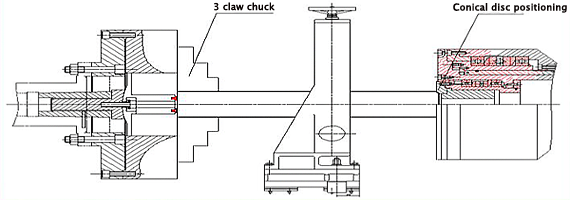

The first way:

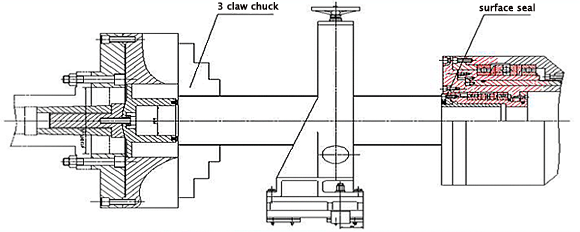

Three-claw chuck is used for clamping, Oil-supply conical disc position, central support can be chosen; Suitable for holing of small diameter; Oil-supply can be used for boring.

The second way:

Three-claw chuck, Oil-Supply end face sealing and central support is used for clamping; Suitable for holing of large diameter; Oil-supply can be used for boring.